As part of our commitment to innovative and environmentally friendly automotive care, we embrace techniques that not only enhance the quality of our service but also protect the planet. Dry ice blasting is one of these revolutionary methods that has transformed how we approach vehicle restoration and repair. This technique is not only effective but also provides a cleaner, safer alternative to traditional cleaning methods, which often involve harsh chemicals and generate waste.

Dry ice blasting uses solid CO2 pellets, which sublimate upon contact, meaning they turn directly from solid to gas without leaving any residue. This unique property makes dry ice blasting an ideal solution for cleaning without contributing to landfill waste or water usage. In addition, this method is incredibly efficient in removing contaminants, paint, rust, and other materials from various surfaces without the abrasion or damage associated with sandblasting or chemical cleaning.

What Is Dry Ice Blasting?

Dry ice blasting is a cutting-edge cleaning technology that we use to maintain and restore vehicles efficiently and effectively. This method involves propelling pellets of solid carbon dioxide (CO2) at a high speed using specialized blasting equipment. Unlike traditional methods that use abrasive materials or chemicals for cleaning, dry ice is non-abrasive and evaporates on contact. This means it can clean surfaces without damaging them.

The process works through a combination of kinetic and thermal effects. When the dry ice pellets hit the surface, they create a micro-explosion that loosens the dirt or contaminants. Because the pellets are extremely cold, they also cause the dirt to shrink and detach more easily. After striking, the dry ice sublimates, turning directly from solid into gas, leaving behind no residues, just a clean surface. This approach is not only highly efficient but also avoids the secondary waste commonly associated with sandblasting or water-based cleaning methods.

Environmental Benefits of Using Dry Ice Blasting

Choosing dry ice blasting offers significant environmental advantages. First and foremost, it eliminates the need for harmful chemical cleaners, which can leave toxic residues that harm both the environment and human health. By avoiding chemicals, we prevent potential pollutants from entering water bodies or soil, protecting ecosystems and reducing our environmental footprint.

Another major benefit is the avoidance of water waste. Traditional cleaning methods can require large amounts of water, but since dry ice sublimates into gas, there’s no water involved in the cleaning process. This feature is particularly beneficial in areas where water conservation is a priority, helping us adhere to sustainable practices.

Moreover, dry ice blasting drastically reduces waste disposal. Traditional methods often result in secondary waste from spent abrasives or dirty water that needs to be treated and disposed of safely. With dry ice blasting, the only waste is the material removed from the cleaned surface, as the blasting medium itself disappears. This not only simplifies the cleanup process but also diminishes the costs and environmental impact associated with waste disposal.

Comparing Dry Ice Blasting to Traditional Cleaning Methods

When comparing dry ice blasting to other traditional cleaning techniques like sandblasting, solvent cleaning, or high-pressure water jets, the differences in efficiency, safety, and environmental impact become quite apparent. Traditional methods often involve abrasive materials that can damage the underlying surface of the vehicle, requiring additional repair work and potentially shortening the lifespan of the vehicle’s components. In contrast, dry ice blasting is non-abrasive and preserves the integrity of the surface being cleansed.

Moreover, methods like solvent cleaning involve hazardous chemicals that can pose health risks to our technicians and clients, as well as environmental risks if improperly handled. Dry ice blasting, on the other hand, uses CO2 pellets that sublimate, leaving no toxic residues or volatile organic compounds. Additionally, techniques requiring large volumes of water can contribute to resource depletion and result in problematic wastewater disposal. Dry ice blasting sidesteps these issues entirely, offering a cleaner, greener alternative that aligns with our commitment to sustainability.

Implementing Dry Ice Blasting in Auto Restoration and Repair

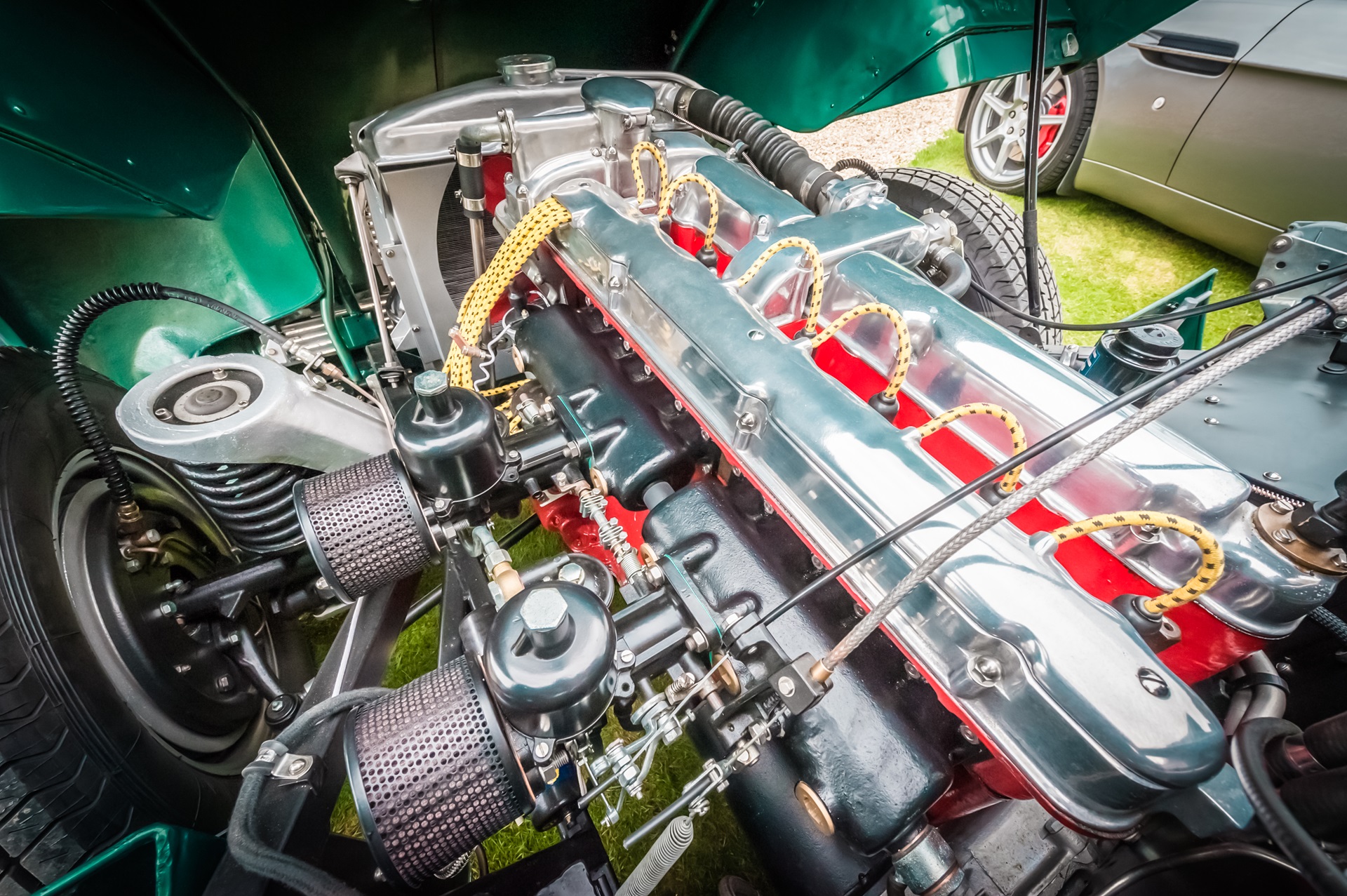

As we continue to push forward in our journey toward more sustainable auto restoration and repair, implementing dry ice blasting has proven essential. This technique is particularly effective in preparing vehicles for repainting by efficiently removing old paint or rust without risking damage to the metal surfaces. It’s also invaluable for cleaning intricate engine components and electrical systems, where precision is crucial and traditional washing methods might cause harm or short circuits.

Given its effectiveness and environmental benefits, we’ve integrated dry foot blasting into numerous stages of our restoration and repair processes. Whether it’s a complete overhaul or a minor repair, using dry ice blasting ensures that we can deliver top-quality results while keeping health, safety, and environmental standards at the forefront.

Conclusion

At Allyz Auto, we take pride in not merely following but setting industry standards, particularly in adopting innovations that offer both operational excellence and environmental stewardship. Dry ice blasting is a testament to our dedication to providing advanced, eco-friendly solutions that don't compromise on quality or performance.

If you're looking to restore or repair your vehicle and want it handled with the utmost care and consideration for the environment, our dry ice blasting services are your best choice. Reach out to Allyz Auto today and experience why our cutting-edge, environmentally-friendly cleaning technology is the preferred choice for preserving the beauty and functionality of your vehicle. Let us help you maintain your car in a way that’s clean for your vehicle and green for the planet.